Capabilities

Dude Garments produces customized uniforms for small and large corporations, brands, schools, hotels, military, government, medical institutions, etc. We are a one-stop customized uniform manufacturer that can provide you with any type of specification you want for your uniform collection, and with our wide range of experience in uniform production, our customized uniforms not only meets but also exceeds the highest industry standards!

What We Offer

We aim to provide a high quality service and help our clients achieve the various types of customization they are looking for, we also offer flexible customization packages that can easily fit your budget and provide you with maximum customization in the process!

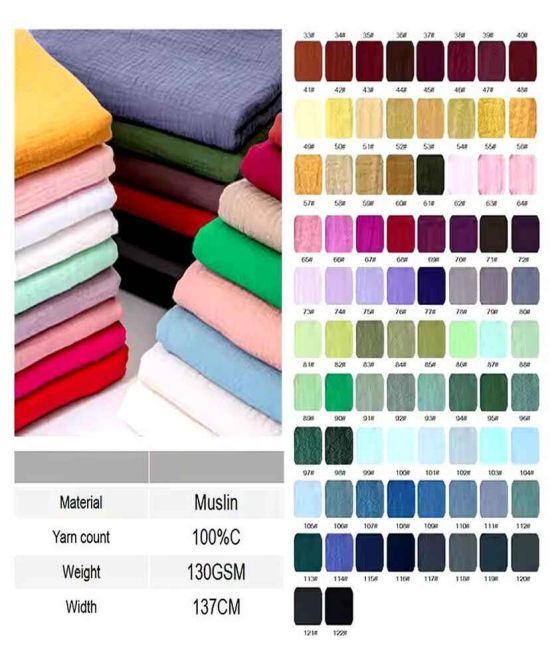

Fabric customization

Customized Printing

Custom Embroidery

Choice Of Thread

Customized Packaging

Get Your Custom Uniforms By 7 Easy Steps

What makes us a leading custom uniform manufacturer is that we provide a comprehensive end solution from concept design to final product. As your uniform manufacturing partner, we make it easy for you to brand yourself and fully complete your uniform collection. Whether it is design, sewing, cutting samples, production, customization, grading, size, color or packaging to production, we can complete every link efficiently and perfectly. We provide you with comprehensive, coordinated and professional services to ensure that your custom uniform project is successfully realized.

01 Consulting Design

The initial stage of garment production begins with making garment samples or blueprints based on customer requirements. Designers use specific details such as design, style, color, size, and personalized prints to create concept designs or sketches of garments, often called garment prototypes.

02 Sampling Confirmation

We make the first batch of garment samples based on the details provided by the customer and send them to the customer for inspection and approval. These samples are made according to customers’ specific requirements. Only after the garment is approved by the customer and meets all quality standards will we begin formal production.

03 Fabric Cutting

We use state-of-the-art automatic and manual cutting machines to cut large quantities of fabrics. This process is extremely precise and meticulous, as even small mistakes can cause irreparable problems. A professional team oversees the cutting process to ensure it goes smoothly.

04 Customized embroidery printing

After completing the precise cutting of the fabric, we perform customized embroidery or printing according to the customer’s requirements. Our embroidery machines are efficient and flexible, capable of producing any pattern that meets the latest design requirements. In addition, we provide a variety of printing methods, including sublimation, screen, heat pressing and DTG printing (Direct-to-garment printing), to meet the personalized needs of different customers.

05 Sewing

Sewing work is done by our experienced workers. We make sure every inch of your garment’s stitching is precise. We are confident that you will not find any flaws in the sewing of our products.

06 Quality Inspection

Once the garments are produced, they will go through our strict quality control system. Any garment found to be defective will never be delivered to the customer. No garment leaves our manufacturing facility unless every requirement is met.

07 Packaging and Transportation

Finally, we use automatic packaging machines to package the best quality products, and these machines can quickly complete the packaging of the products in a short period of time. Once the order is packed, it will be sent to your location with minimal shipping time.